Low-cost acid and base in a modular format with superior environmental and operational attributes will enable massively affordable decarbonization

Silicate Glass Refinery

They said it couldn’t be done. For decades, sodium silicate production has relied on high-heat processes and sodium carbonate, generating 2–4 tons of CO₂ for every ton produced and leaving a $10 billion global industry with a significant carbon footprint. EDAC has changed the game by discovering a carbon-free source of silicates: recycled glass. Readily available worldwide and at very low cost, recycled glass is now the foundation of EDAC’s breakthrough. We are the first company to successfully upcycle glass into technical-grade sodium silicate.

Powered by our proprietary Electrosynthesizer—the world’s lowest-cost technology for producing acid and base—EDAC is positioned to offer the lowest-cost, highest-quality sodium silicate on the market. Our sodium silicate serves a wide range of industries, including detergents, water treatment, construction materials, adhesives, and as a key precursor for amorphous silica used in tires, pharmaceuticals, toothpaste, coatings, colloidal silica, and silica gels. By combining innovative technology with sustainable sourcing, EDAC is redefining the future of sodium silicate with superior quality, lower costs, and a dramatically reduced carbon footprint.

Carbon-Neutral Silicate Rock Refinery

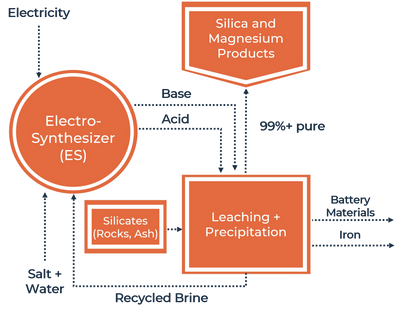

Ultramafic rocks contain silica, magnesium, iron and critical minerals such as nickel, cobalt and manganese. Mafic rocks and ash contain silica, magnesium, iron and alumina. We process these rocks with a technology called "hydrometallurgy" that uses acid and base to leach (dissolve) rocks, and then base to precipitate (make liquid into solid) out the minerals we want. This process is mass-balanced, which means it creates virtually no waste and no emissions. Our feedstocks are silicates, which means when we process them, there are no carbon dioxide emissions! Thus, EDAC provides the most environmentally friendly mining process.

EDAC's Silicate Rock Refinery produces 99%+ pure silica and magnesium products that are low cost and carbon-free. We generate our own acid (HCl or H2SO4) and base (NaOH) using our proprietary Electrosynthesizer that makes acid and base at less than half the cost of chlor-alkali.

We can further refine our products to produce amorphous silica, waterglass (sodium silicate), precipitated silica, magnesium hydroxide, magnesium oxide, and magnesium chloride. Most incumbents use high heat processes that emit CO2 when making these products. We also create iron oxides and hydroxides and nickel, manganese and cobalt hydroxides (MHP) for batteries.

Magnesium-silicate rocks are a Global Opportunity

At 3% of the earth's crust, ultramafic rocks can provide limitless magnesium and solve the climate crisis many times over

Carbon-Removal with Critical Minerals Extraction

By adding an air contactor to our magnesium refinery, we literally capture CO2 from the air and insert it into our magnesium hydroxide to create magnesium carbonate, an inert sand-like substance. This approach provides permanent capture and sequestration of CO2. The United States has so much ultramafic rock that using EDAC's process, it could sequester 4 trillion tons of CO2.

Lithium Recycling

EDAC's electrosynthesizer can split both lithium and sodium salts. For some battery recyclers, the process flow includes the creation of Lithium Sulfate and Sodium Sulfate waste. EDAC can manage both of these streams to produce the final Lithium Hydroxide used in batteries, and to help recycle the sodium sulfate waste into use streams of sodium hydroxide (base) and sulfuric acid.

Direct Air Capture

The electrosynthesizer cost effectively makes acid and base to capture CO2 from air and release it as a pure CO2 stream in a fully mass-balanced process with no waste or emissions.

Electrosynthesizer Sales for Other Applications

EDAC Lab’s Electrosynthesizer will be available for sale to support a variety of applications, including mining, iron making, industrial waste recycling, wastewater treatment, and more. This solution is fundamentally modular, can be located on-site, and can generate the amount of acid and base needed for your application at about half the cost of chlor-alkali and without any hazardous emissions or waste. It can be modified to generate different acid/base pairs, for example sodium hydroxide and hydrochloric acid from sodium chloride, and sodium hydroxide and sulfuric acid from sodium sulfate. In some applications, brine can be recycled back to the Electrosynthesizer to save costs.

Copyright © 2024 EDAC Labs - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.